While the newly FDA approved COVID-19 vaccines from Pfizer and Moderna are a welcome reprieve from the effects of the pandemic in 2020, hospital pharmacies face an immensely complicated roll-out. As 2020 ended, American hospitals needed to pivot overnight to store a temperamental vaccine presentation, outfit their hospitals as vaccination centers, and ensure they are properly stocked with the vaccines themselves, ancillary supplies, and the staff to make the roll-out successful. This is a tall order, especially after months of pandemic clinical stress and potentially related staffing issues.

Alan Portnoy, Pharm.D., Pharmacy Operations Manager at Reading Hospital in Reading, Penn., reached out to Kit Check with a big problem in January 2021: their vaccine inventory counts were incorrect at the end of each day. Dr. Portnoy and his team order new doses of vaccines from the Pennsylvania State Health Department, depending on how many vials his team uses every day at the vaccination clinic. With intense demand for the vaccine and 5+ doses in the Pfizer vaccine vial and 10 doses in the Moderna vial – item-level visibility into every vial of vaccine is more important than ever. Before connecting with the Kit Check team to create an RFID-enabled inventory management solution for the vaccines, Reading Hospital was relying on inventory counts written in marker on the vaccines’ ultra freezer door.

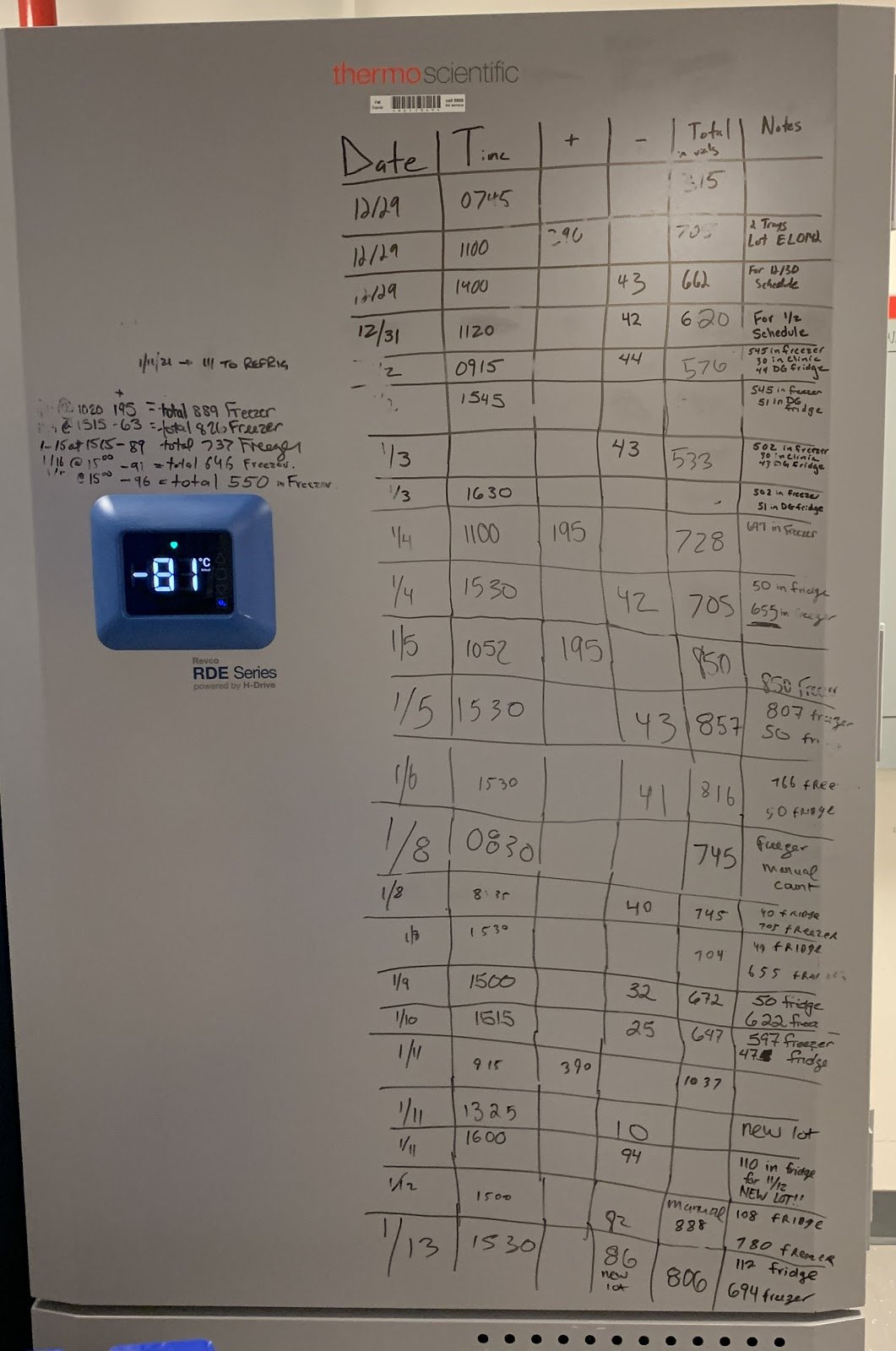

The manual inventory workflow the Reading Hospital team was using was error-prone.

It required counting the vials by hand

- When vaccines left the ultra freezer

- When vaccines were transported to the vaccination clinic,

- And again when the unused vaccine vials were returned to the refrigerator

That is a lot of touchpoints for human error!

On top of the highly manual nature of this restocking workflow, once a Pfizer vaccine leaves the ultra freezer it is viable for 5 days in the refrigerator, another data point that is easy to miss with manual restocking. If a vial expires after that 5 day Beyond Use Date, that is 5+ doses of the COVID-19 vaccine wasted, the dire importance of which cannot be overestimated.

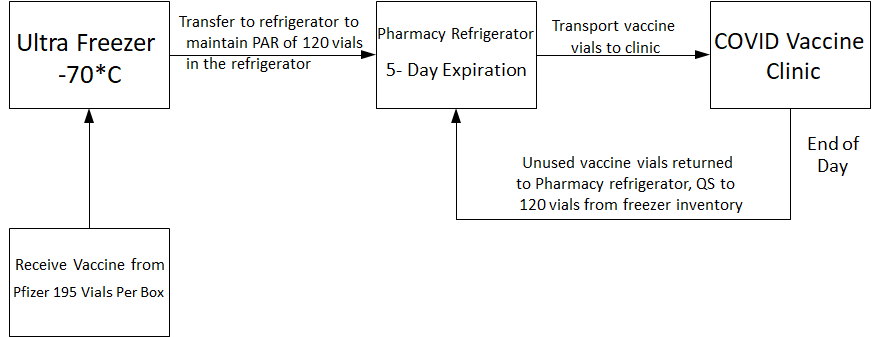

Manual Pfizer Vaccine Inventory Workflow

Dr. Portnoy, a Kit Check user since 2019 and frequent collaborator, knew there must be an easier and more precise way to account for vaccine inventory using Kit Check’s RFID-enabled inventory management solution. Dr. Portnoy is no stranger to RFID innovation to battle the COVID-19 pandemic. As noted in Pharmacy Practice News, Reading Hospital was one of the first Kit Check customer sites to use the Sanitization Check feature earlier on in the pandemic to ensure kits and trays that were potentially exposed to a COVID-positive patient were cleaned properly to prevent contagion.

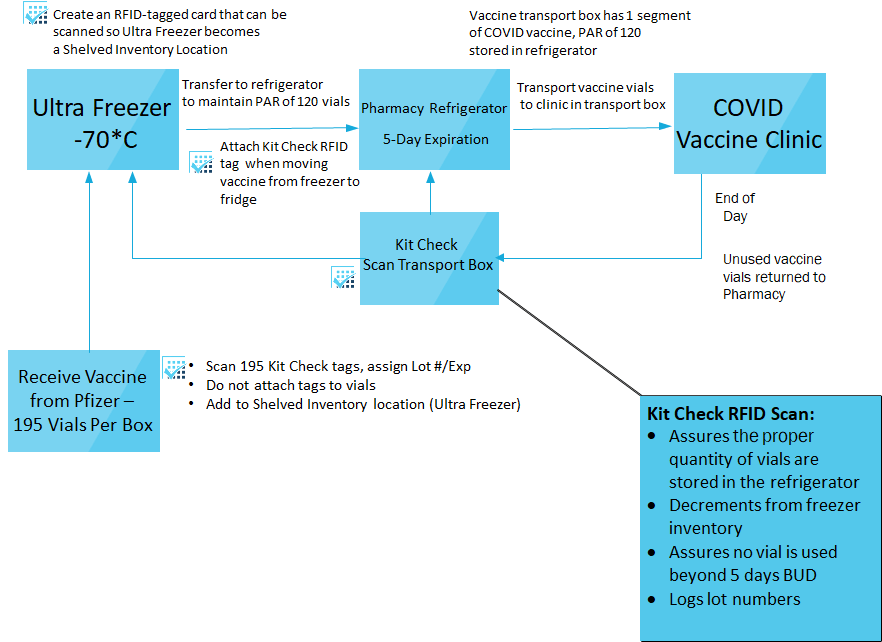

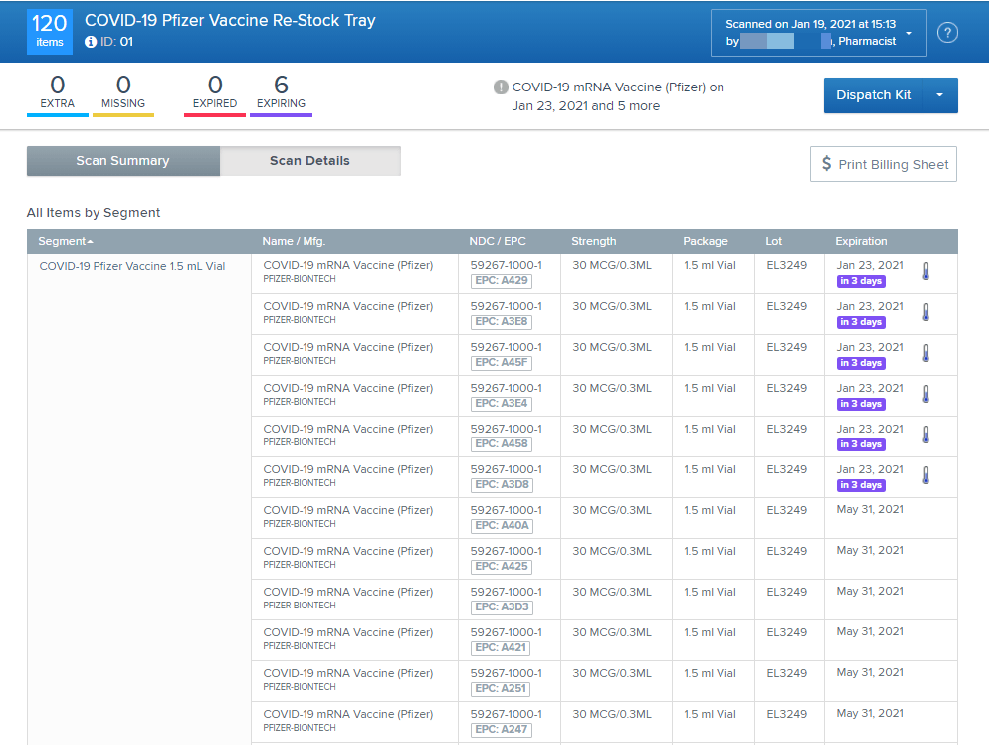

With 600+ administrations a day, Dr. Portnoy and the Kit Check team were able to quickly come up with a solution that allowed for a cloud-based inventory record of each and every vial of vaccine, so counts were accurate and more people could be vaccinated. RFID is uniquely poised to help in complicated hospital supply chain management use cases like this – as tags can be encoded with pertinent dose-level information, like lot number or expiration, and edited with new information with each scan, like setting the Beyond Use Date clock “ticking” when the vial is removed from the ultra freezer and scanned in the Kit Check scanning station.

The Kit Check team worked with Dr. Portnoy to prepare the Reading Hospital satellite vaccination storage area, complete with the requisite ultra freezer, with a Kit Check RFID scanning station. Using the Shelved Inventory feature of the product, now, when Dr. Portnoy receives a shipment of the Pfizer vaccine, he creates, prints, and scans 195 RFID labels into the Ultra Freezer shelved inventory location. Each RFID tag is encoded with the shipment’s lot number and expiration. When vaccines are removed from the ultra freezer, they must sit out for a few minutes to warm up, and then a technician can apply the pre-printed lot-specific Kit Check RFID label to each one and scan them in the Kit Check scanning station to start the 5-day BUD countdown. Dr. Portnoy created a vaccine kit with an anesthesia drawer liner with a set PAR of 120 vials that remains in the refrigerator and is refilled at the end of each day.

Pfizer Vaccine Inventory Workflow using Kit Check

Pfizer Vaccine Kit Contents in the Kit Check Application

The Reading Hospital pharmacy team is better positioned to tackle this complicated inventory management challenge. “We are now better able to track COVID vaccine inventory”, said Dr. Portnoy. “There is a real need for this as we are reporting usage back to the Pennsylvania Health Department for the next shipment. We are going through over 600 doses a day and with RFID we can keep track of lot numbers, track the number of doses used, and ensure no vials expire after leaving the ultra freezer, so it has been worth the time investment setting up the Kit Check workflow”.

A Quick Guide to Setting up your COVID-19 Vaccine Kit

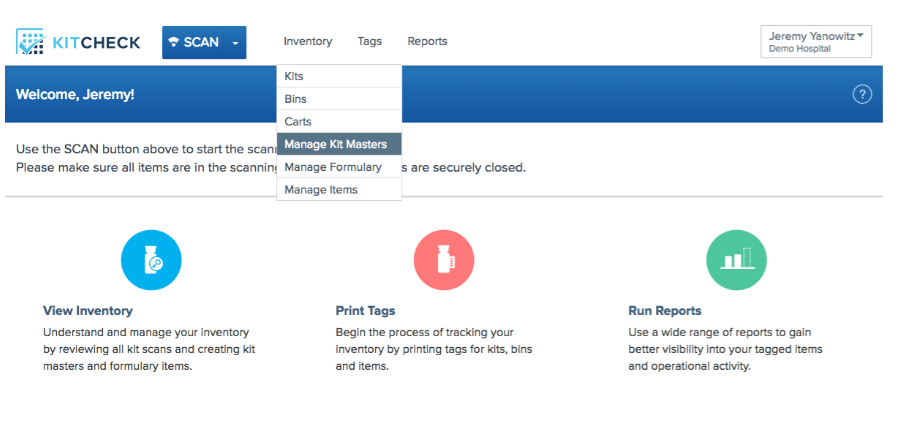

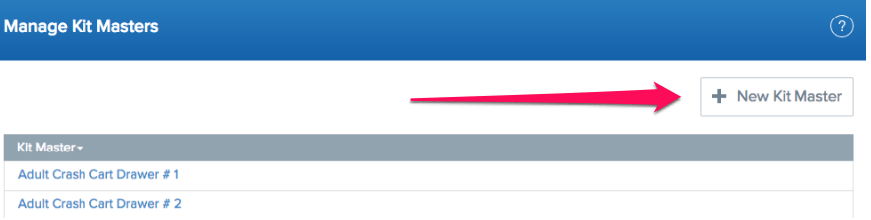

The “Manage Kit Masters” function allows users to add a new kit master, edit existing kit masters for changing quantities or drug requirements, clone kit masters, and associate what items are included in a kit.

Adding a Kit Master

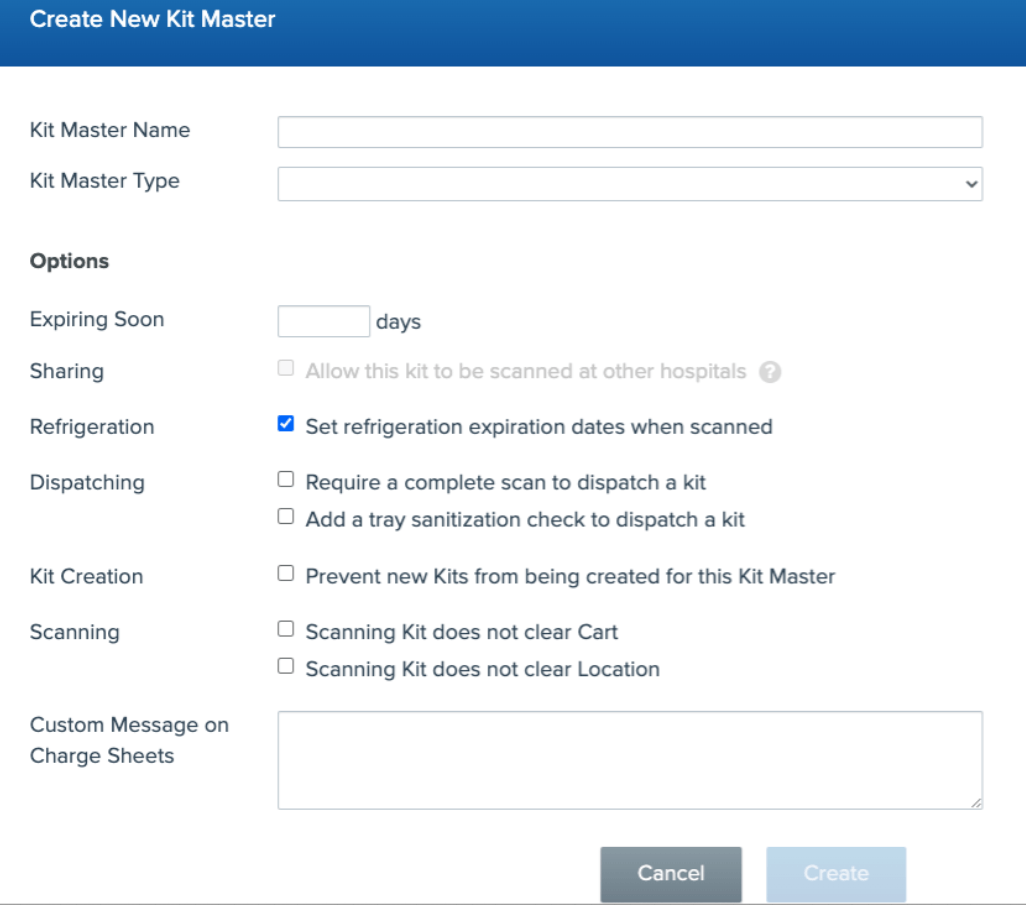

To add a new kit master, select the ![]() button. Then enter the name of the new kit master. Users can also update the kit master type, as well as refrigeration and expiring soon settings. Hospitals with the Shared Kits feature enabled can also identify a kit master as shared to allow other hospitals to scan and process kits of this kit master.

button. Then enter the name of the new kit master. Users can also update the kit master type, as well as refrigeration and expiring soon settings. Hospitals with the Shared Kits feature enabled can also identify a kit master as shared to allow other hospitals to scan and process kits of this kit master.

Users can use the Custom Message on Charge Sheets field to include regulatory language or any other custom text to be printed on the bottom of charge sheets for the selected Kit Master.

For more information about using Kit Check to navigate the COVID-19 vaccine roll-out in your hospital, please contact your Solutions Consultant.