Improving Kit Accuracy

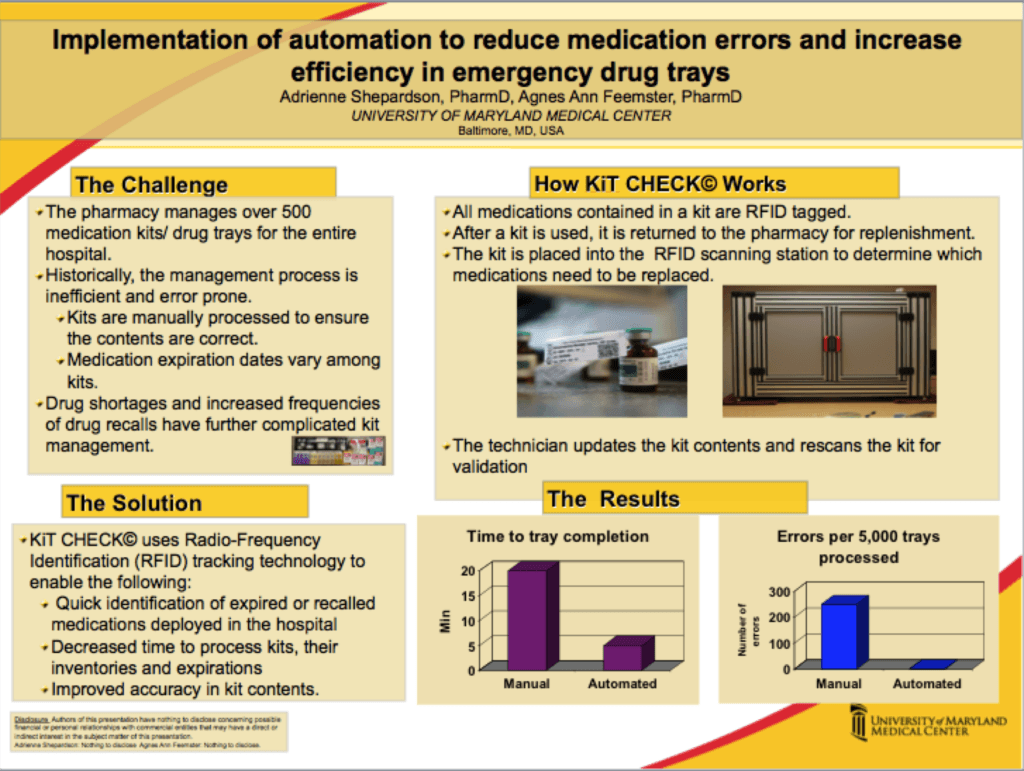

We all know that manual processes introduce the risk of human error. When you have a high volume process such as pharmacy kit / tray restocking, errors add up quickly. This translated into 1,000 medication stocking errors annually with a rate of 250 errors per 5,000 pharmacy trays processed. Based on my experience as a Director of Pharmacy and seeing hundreds of hospital pharmacy operations throughout my career, this kit error rate is common.

Stocking errors range from the presence of expired or incorrect medications to improper strengths. Each of these could lead to an adverse drug event.

Human Double Check – Not Effective Enough

All of these errors occur annually despite state board of pharmacy requirements that registered pharmacists double-check the stocking accuracy of pharmacy technicians. To be clear, for these kit errors to occur they must pass through both technician and pharmacist checks. We all know that humans get distracted, tired and overconfident when performing tedious, repetitive tasks. The result here is potentially thousands of incorrect pharmacy kits.

Errors fell to near zero with Kit Check according to the UMMC presentation. When checking for kit accuracy, the RFID reader doesn’t get distracted, tired or overconfident. The software treats every pharmacy kit the same and automatically verifies every medication as correct and within expiration.

A Lot More Efficient, Too

A Lot More Efficient, Too

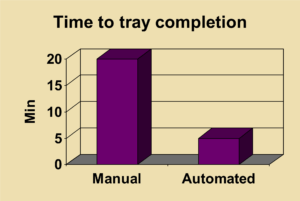

Conducting a machine check to reduce the risk of medication stocking errors alone should justify implementing Kit Check’s RFID solution or adopting a barcode approach. However, with Kit Check you also capture significant efficiency gains that more than pay for the system. An average hospital can save $4.07 per kit medication. UMMC estimates that its processing time was reduced by over 75%. That is a lot of saved labor.

When you consider your pharmacy kit plans for 2014, reflect on what UMMC reported at ASHP this year. The pharmacy staff saw an opportunity to protect patient safety through improved kit accuracy and cut operating costs at the same time. That outcome is good for patients and the hospital.