“Technicians love this. They absolutely love this because it’s easy. It makes a very overwhelming task much more manageable. It decreased their time to fill. It’s a better management of expiring medications because you can pre-order and know what’s out there expiring. We have the ability to recall medications if needed,” said Dianne Shoemaker, the Allied Health Technical Coordinator overseeing pharmacy technicians at the University of Michigan Hospitals, to an ASHP audience during a management case study presentation on the use of Kit Check.

“Technicians love this. They absolutely love this because it’s easy. It makes a very overwhelming task much more manageable. It decreased their time to fill. It’s a better management of expiring medications because you can pre-order and know what’s out there expiring. We have the ability to recall medications if needed,” said Dianne Shoemaker, the Allied Health Technical Coordinator overseeing pharmacy technicians at the University of Michigan Hospitals, to an ASHP audience during a management case study presentation on the use of Kit Check.

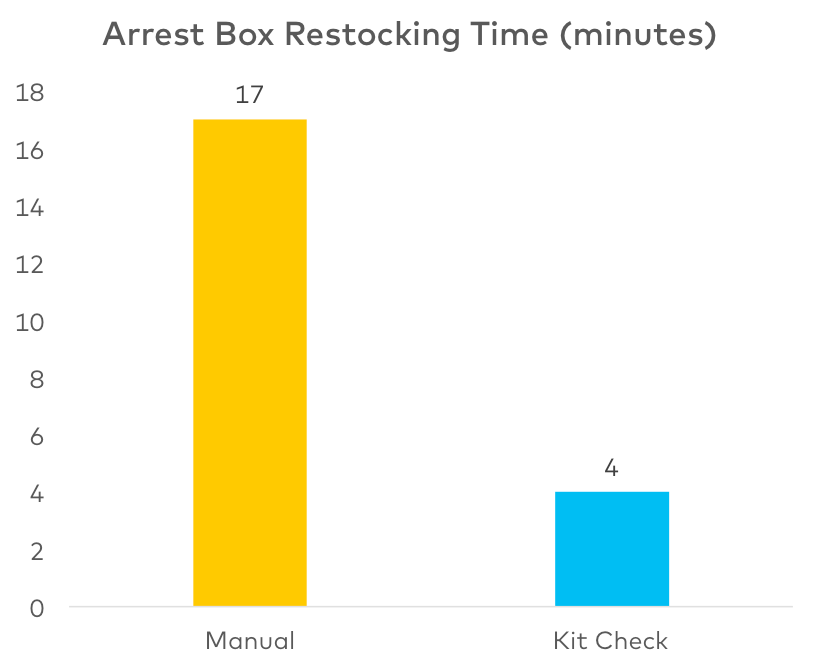

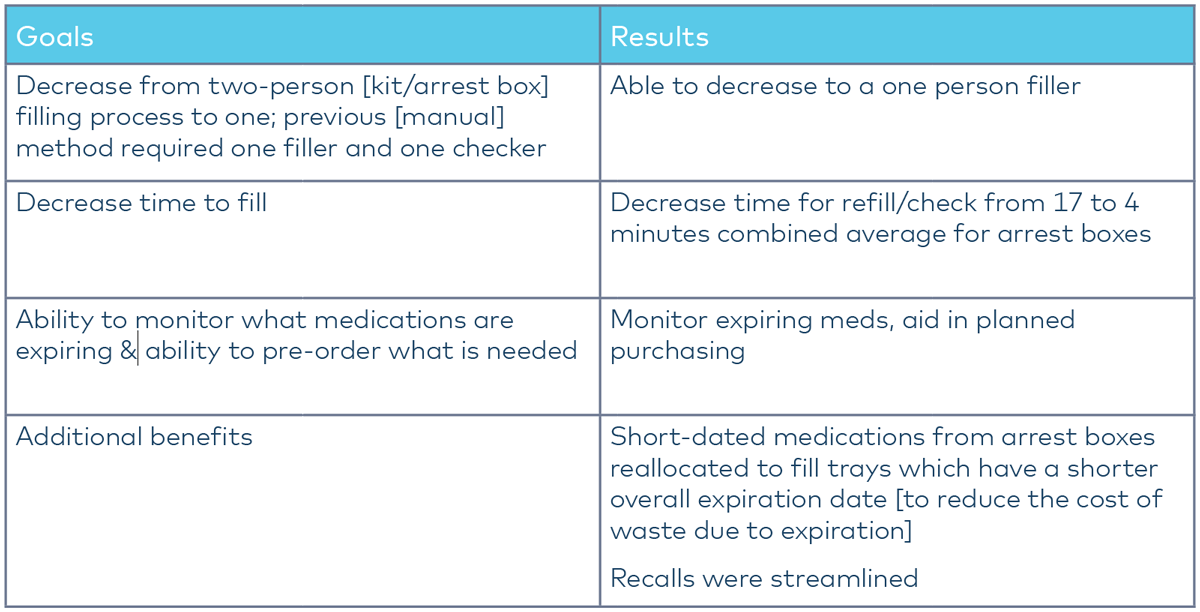

Why do the Michigan hospital technicians love Kit Check? Part of it can be traced to the results. Restocking pharmacy kits at the hospital fell from an average of 17 to just 4 minutes after implementing the solution. “Some of the ICU trays take less time than that.” The result is a 76.5% decrease and falls within the user-reported range of 71-96% time savings. However, they also like the system because it’s easy to use and addresses some common challenges associated with code carts and arrest boxes.

Why do the Michigan hospital technicians love Kit Check? Part of it can be traced to the results. Restocking pharmacy kits at the hospital fell from an average of 17 to just 4 minutes after implementing the solution. “Some of the ICU trays take less time than that.” The result is a 76.5% decrease and falls within the user-reported range of 71-96% time savings. However, they also like the system because it’s easy to use and addresses some common challenges associated with code carts and arrest boxes.

Project Goals

The University of Michigan Hospital has 950 beds supported by 153 crash carts, 349 arrest boxes, and 37 ICU trays. The pharmacy staff implemented Kit Check with specific documented goals and the summary by Shoemaker was clear when she said, “we achieved all of our goals.”

Easy-to-Use was a Key Theme

Ms. Shoemaker also elaborated further in the slide discussing results saying that, “The software is very easy to use. The labels are easy to apply. Once you do fifty of them you’ve got it down pat.” This was a sharp contrast from the previous manual process.

Ms. Shoemaker continued, “Before we started with this RFID system, we were doing everything by hand. We would get a box back that was either used or expired. Then we would have to take the medications and find what was missing because we didn’t know what was used. Then you would refill [the kit] and then check to see which drugs were expiring…Everyone had their own system for doing this. Then we had a manual second check for these arrest boxes.” All of the data collection on the kit contents from expiration date to people processing the arrest boxes was done manually.

With Kit Check, the users simply place a kit into the scanning station and, “it tells us everything that was in the arrest box. It could tell us the lot number, the expiration date. It would tell us if we were missing anything…which is the first one to expire. It tells us everything.”

Ms. Shoemaker also did a good job explaining the two types of tags used by the University of Michigan Hospital. Most people are familiar with the medication tag which is applied directly to the vial, box or ampoule. These tags are used to track the medications and identify which medications were used or nearing expiration and need to be restocked when a kit returns to the pharmacy. The second tag is the same type in form, but its function is different. It identifies the kit and enables users to track kit locations and inventory.

This capability came in handy during a recent recall of Auvi-Q. Of the 49 arrest boxes that contained Auvi-Q, she was able to determine in just a few clicks in the Kit Check software that none of the boxes contained the recalled lot number. Instead of pulling 49 arrest boxes from clinical areas to confirm the lot number was not present, she determined in seconds that the effort was unnecessary. This saved a lot of time that otherwise would have been wasted. If the lot number was present in some arrest boxes, she could have simply pulled the subset that were impacted. The kit tag location data lets users know where to quickly find arrest boxes and other kits when required.

Using Data to Improve Operations and Inventory

Ms. Shoemaker also commented on the value of the Kit Check reports and analytics capabilities for purchasing and inventory management. “We were able to monitor expiring meds and that helped us with our purchasing. If we saw a drug that we don’t use very often, like our lidocaine bags, we can look that up ahead of time to see what is expiring in our boxes and pre-order it…to have it on hand and ready to go.”

She also commented that there were drugs the staff believed were not used very often but it was a perception that they couldn’t prove. Kit Check’s reports provided the data to prove their instincts were correct. She commented, “People don’t like to go by perception. They like data. We were able to use hard data to show this [drug] had not been used in years and we took it to our CPR committee and had it removed.”

More than Efficiency, Staff Enthusiasm, Accuracy and Inventory Benefits

Kevin MacDonald commented in Monday’s blog post that many people believe that 9 out of every 10 hospitals choose Kit Check to automate pharmacy kit restocking because of the strong ROI. Presentations at ASHP Midyear by St. Rita’s Medical Center (79.6% more efficient) Monday and the University of Michigan (76.5% more efficient) Tuesday reinforce that perception.

While these results are important, we are seeing more stories everyday from users like Diane Shoemaker. The ease of use, staff enthusiasm, reduction in fill errors and ability to use data to improve inventory and purchasing practices are equally or more important to users. These factors lead hospitals to choose Kit Check instead of imitation products that are less robust.

If you would like to learn more about Kit Check and the experience of other hospital users, you can check out some of our customers by clicking here. You can also schedule a demo by clicking here.