80.4% Faster Kit Processing

Earlier longitudinal studies of hospital pharmacy kit populations have consistently shown average restocking time savings of 72-90% when using Kit Check. The peer-review study conducted by Summerfield Consulting’s Marc Summerfield (M.S., RPh) with statistical analysis by Yan Xiao (Ph.D.) of Baylor Scott & White Health found an 80.4% average time savings. This included a variety of kits from different size hospitals, including:

- Hospital A: 569-beds

- Hospital B: 687-beds

- Hospital C: 276-beds

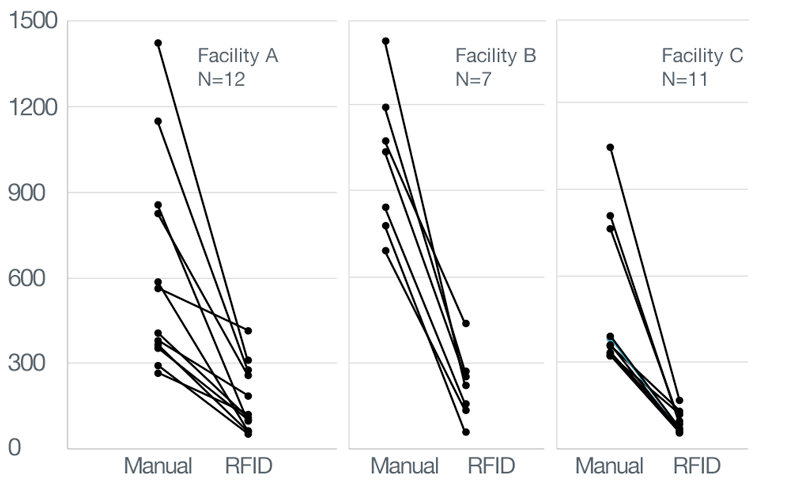

You can see from the chart above that a wide variety of manual restocking times were observed. The primarily driver of these differences were kit size and configuration variance. However, the RFID (Kit Check) solution shows a much narrower clustering of restocking times across kit types and across hospitals. This is expected.

You can see from the chart above that a wide variety of manual restocking times were observed. The primarily driver of these differences were kit size and configuration variance. However, the RFID (Kit Check) solution shows a much narrower clustering of restocking times across kit types and across hospitals. This is expected.

Kits that are large and complex require more manual time for restocking. By contrast, when using RFID technology all kits take about the same amount of restocking time and the process is faster regardless of kit size and complexity. With Kit Check, it takes about five seconds to determine what medications need to be restocked and if any should be removed due to expiration. This is followed by the restocking step and another five seconds to verify the kit is correct. The conclusion is clear that time savings are available regardless of hospital size or kit variation.

Save $4.20 to $9.30 Per Kit Processed

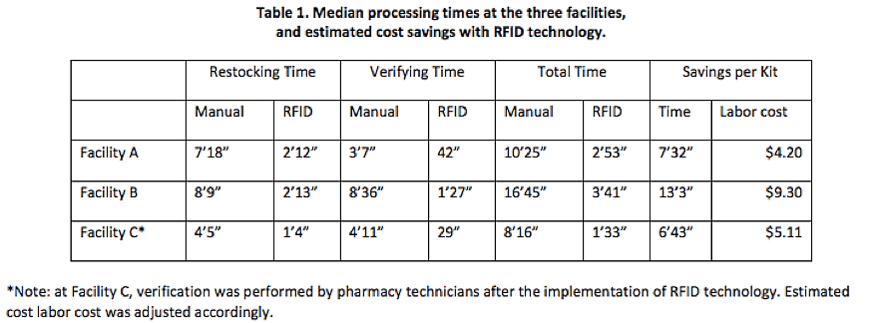

The study also considered the labor cost impact of the observed time savings. Savings originate from reduced kit restocking time for both pharmacy technicians and pharmacists. The labor rates used in the study of $20.50/hour for technicians and $61.00/hour for pharmacists are on the low end of expectations, but the results still suggest a substantial savings ranging from $4.20 to $9.30 per kit restocked.

The implication here is two-fold. First, hospital pharmacies can capture substantial savings today regardless of kit size and complexity or hospital size. Second, the faster kit processing enables new kit usage that some hospitals avoided when manual restocking was the only viable method. For example, many hospitals chose not to use pharmacy kits for anesthesia because of concerns about daily restocking times. The streamlined processing offered by Kit Check’s automation solution makes anesthesia and other kits a faster and more consistent dispensing method than any available alternatives.

The implication here is two-fold. First, hospital pharmacies can capture substantial savings today regardless of kit size and complexity or hospital size. Second, the faster kit processing enables new kit usage that some hospitals avoided when manual restocking was the only viable method. For example, many hospitals chose not to use pharmacy kits for anesthesia because of concerns about daily restocking times. The streamlined processing offered by Kit Check’s automation solution makes anesthesia and other kits a faster and more consistent dispensing method than any available alternatives.

How Will You Use Your Time and Cost Savings

As a pharmacy director, it always bothered me that my team of highly trained and highly compensated pharmacists was checking kits. I understood the necessity of the work to ensure safety, but the repetitive manual process seemed better suited to automation than skilled staff. Kit Check provides that automation and according to this peer-reviewed article, confirms once again that 80% or more time savings is available today regardless of hospital size.

Some Kit Check customers have used this time savings to reduce overtime costs, others have redeployed staff to safety programs and some have been able to refocus pharmacists on clinical activities. The question for pharmacy directors I work with is, “How will you use your time savings?”

To learn more about Kit Check, take a look at this short product tour and video.