Time Saving from Pharmacy Kit Automation

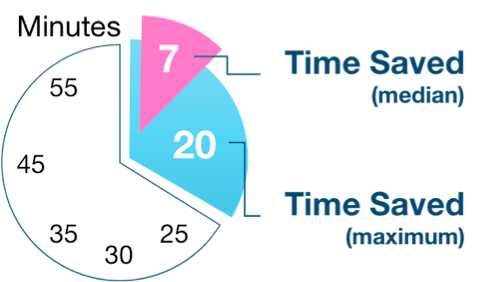

Thirty pharmacy kits were analyzed from the three unaffiliated hospitals. The median time saved per kit restocking process was seven minutes and the maximum time saved was 20 minutes. A Wilcoxon test found the time savings results were statistically significant and highly correlated. One expected finding that was confirmed:

Thirty pharmacy kits were analyzed from the three unaffiliated hospitals. The median time saved per kit restocking process was seven minutes and the maximum time saved was 20 minutes. A Wilcoxon test found the time savings results were statistically significant and highly correlated. One expected finding that was confirmed:

large kits with many medications result in more time savings per restocking event.

The Evidence is Clear and Consistent

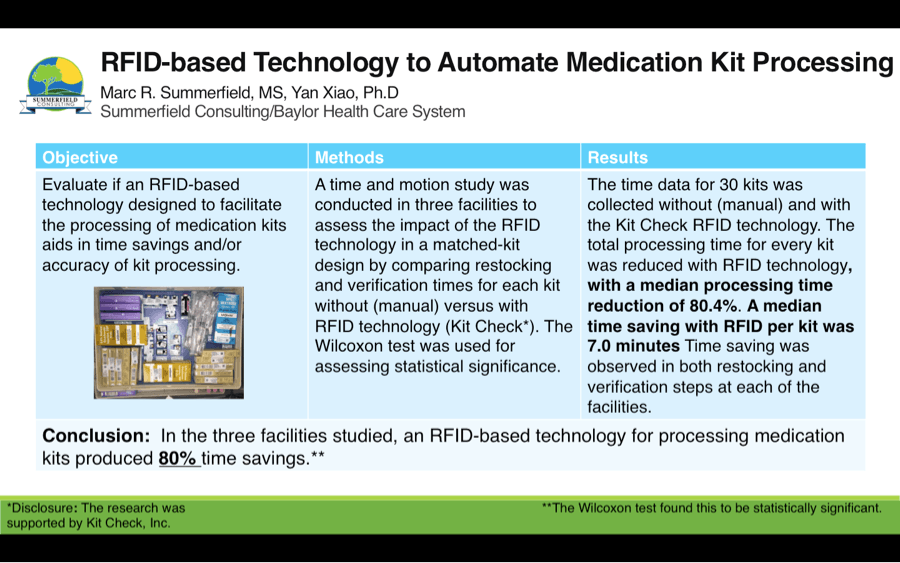

Kit Check is a data-oriented company. Whenever possible, we answer questions from hospital pharmacists by presenting data. The first time and motion study comparing Kit Check to manual pharmacy kit restocking was conducted in 2012 by a pharmacy staff without our input. That analysis concluded an expected range of 76-90% time savings per kit by implementing Kit Check. The key variable driving the range was the number of medications in a kit. As hospitals have conducted additional studies over that past two years, we continually see time savings results in that same range.

Kit Check is a data-oriented company. Whenever possible, we answer questions from hospital pharmacists by presenting data. The first time and motion study comparing Kit Check to manual pharmacy kit restocking was conducted in 2012 by a pharmacy staff without our input. That analysis concluded an expected range of 76-90% time savings per kit by implementing Kit Check. The key variable driving the range was the number of medications in a kit. As hospitals have conducted additional studies over that past two years, we continually see time savings results in that same range.

This latest study comparing results from multiple hospitals reports a median time savings in the middle of the range again: 80.4%. We know that every pharmacy has unique characteristics. However, we are seeing strong consistency in the way hospitals manage pharmacy kits and the benefits they receive when implementing Kit Check to automate the process.

Research Background

The poster was submitted by Marc Summerfield (MS) of Summerfield Consulting and Yan Xiao (Ph.D.) of the Baylor Health Care System. Kit Check provided financial support for the research, but the test design, data collection, data analysis and report compilation were conducted independently by Mr. Summerfield and Dr. Xiao. The tests were conducted at three different hospitals using matched-pair analysis of pharmacy kits, first using the traditional manual restocking approach followed by using Kit Check’s automated solution.