In a typical hospital, the process for dealing with a recall would consume significant, unplanned staff time. Often staff would find themselves on a wild goose chase as they open up every kit, tray and ADC in the hospital looking for potentially recalled items.

Broad reaching drug recalls cost pharmacies years of productivity

This particular recall was massive. At just the 350+ Kit Check customers, there are 15,226 kits/trays/ADC drawers that at one point contained at least one of the recalled NDC’s. Before Kit Check, these Pharmacies would have taken the following steps:

- See if the hospital purchased the NDC/Lot in the past

- Confirm whether or not that NDC was used in kits

- If yes to both of those, open each kit, replace recalled items (if there), re-verify kit

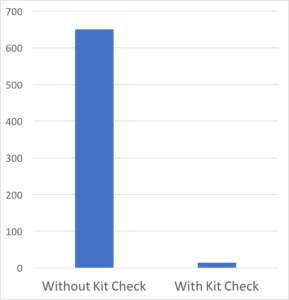

This means 15,226 kits, trays and ADC drawers would need to be located, opened, inspected, fixed (if necessary) and re-verified before being redeployed. Using a conservative 20 minutes per kit estimate (industry average is 20 minutes of a pharmacy tech and an additional 20 minutes of a pharmacist per kit), it would take an individual person 2.5 years, working 8 hours a day, 5 days a week to completely address this one recall.

Person days to process recall

Staff efficiency and targeted responses make recalls manageable for pharmacy leaders and their teams

With Kit Check, however, our customers will spend less than 15 person days to deal with those 15,226 kits. How do you take a process that would take 2.4 person years and cut it down to just 15 person days you ask? It comes down to two huge advantages hospital pharmacies have with Kit Check:

- Item level visibility down to the NDC and Lot

- >90% faster kit processing time

Instead of blindly reprocessing 15,226 trays, we know the exact 2,380 kits that actually have recalled items. And instead of 20 minutes to reprocess each tray, it only takes 3 – 4 minutes. While non-Kit Check customers are spending days of staff time dealing with this unfortunate recall, Kit Check customers are able to quickly address the issue and get back to work.

The power of the cloud and the crowd to increase medication safety

Because of the Kit Check Cloud, we can also leverage the knowledge of one hospital to benefit the entire customer community. A commonly used phrase to describe this approach is “crowdsourcing” and we leveraged this concept to help address two big issues pharmacy leaders face when dealing with recalls:

- Timely awareness of recalls

- Cutting through the noise of recalls that aren’t relevant

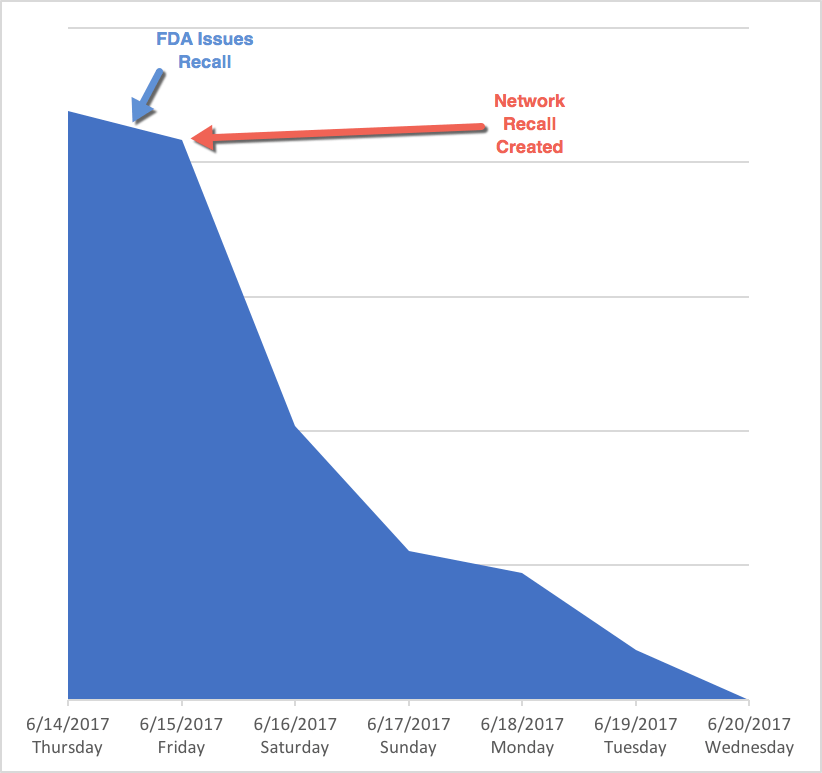

Using our proprietary Network Recall algorithm, Kit Check automatically identifies valid recalls and then proactively notifies only those customers that have recalled items in their inventory. As a result, hospitals that need to can react more quickly to recalls and hospitals that don’t can stay focused. As you can see in the chart below, the Kit Check community was alerted quickly and moved swiftly to remove the recalled items from their inventory.

[su_pullquote align=”right”]“The Kit Check Network Recall alerted our hospital an entire day sooner than the recall service we pay for.” – Director of Pharmacy[/su_pullquote]

Recalled items in kits

Visibility enables Directors of Pharmacy and IDNs to provide leadership during recall events

With Kit Check, Directors of Pharmacy and IDN Pharmacy leaders have complete visibility to monitor and track their team’s progress when dealing with recalls within individual hospitals and across the entire IDN. We sincerely hope that there isn’t another recall of this magnitude anytime in the near future but if you are interested preparing for that inevitable eventuality, contacts us. We can get you up and running on Kit Check and back to focusing on clinical care in less than a week.