You’ve been in the hospital pharmacy world for a while now and have implemented your fair share of pharmacy technology solutions. What are your expectations of how vendors should manage the implementation process and how do those expectations compare to what usually ends up happening?

I expect the vendor to be the subject matter expert in the implementation of their software. The implementation manager should have a tried and true checklist to make sure everything is covered. They should be able to anticipate where things might go wrong and help us plan accordingly.

More often than not, however, that doesn’t happen. There is always something that is forgotten or left out. Things don’t work properly for the first couple of weeks because of this or that. Obviously, process change can be complicated and I don’t expect everything to be perfect. Things happen and I get that. That being said, frequently the vendors don’t do their homework or don’t communicate sufficiently with all the relevant parties. For example, they’ll forget to check with IT or they fail to follow up to confirm the needed prerequisites are in place. Inevitably these oversights have the effect of pushing out the launch date, wasting my team’s time, and eroding confidence before we even begin using the solution.

How did your Kit Check implementation compare with your previous experiences with other products?

When comparing projects that I have done and my recent experience with Kit Check, I personally can’t think of one that has gone smoother, been more seamless or so complete from beginning to end. And I’m comparing that to implementations I’ve done not just here at Ohio Valley but throughout my career.

That is great to hear. What aspects of the Kit Check deployment experience do you think made the biggest difference?

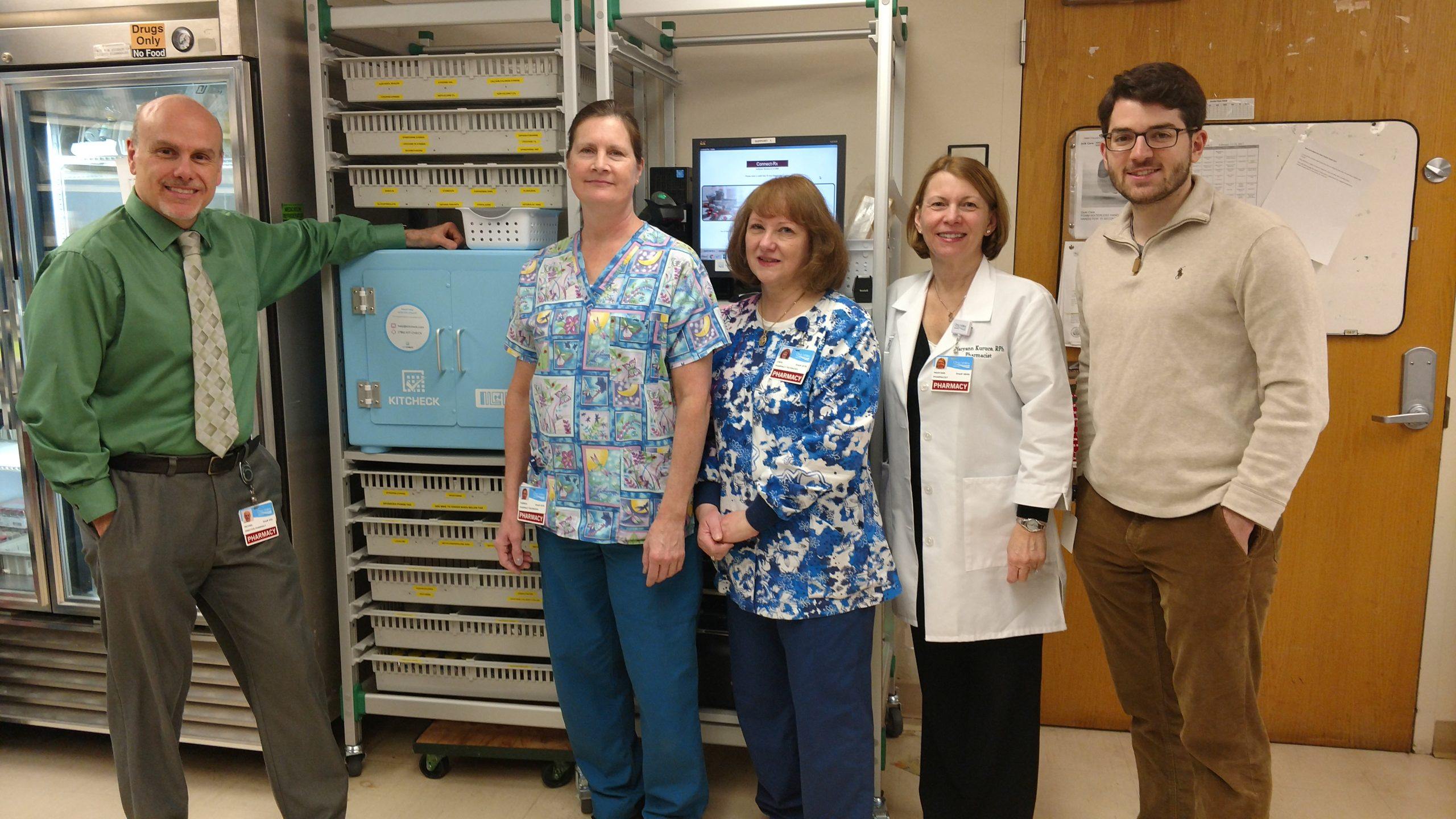

What I liked about working with Kit Check is that they communicated every step with me. When I first met Denette she unrolled the entire product line and everything that went with it and how Kit Check worked. Once we committed to purchasing it, our deployment manager, Tyler, was immediately brought in so there was no gap in communication. You could tell from the start of Denette selling the product to the time that Tyler was helping us wrap up the implementation, that it was a well thought out process and the follow-up was professional. I was very much attuned with their communication which was top of the line. Again, the follow-up was there and the professional demeanor was there. What made it even more impressive was that they were fitting us in on a pretty short notice and yet they were doing it with such a degree of excellence.

What advice do you have for vendors looking to improve their processes that encompass the initial sale through the completion of the implementation?

I think one of the biggest problems with vendors is that they oversell a product. During the sales process, they’ll tell you it will do exactly what you need but when you scratch the surface a bit you find out it only kind of does what you need it to. I call that a half-baked product. In other words, if there is some feature that’s not ready on day one, then it’s not a feature that should be sold. I remember having a conversation with a Kit Check representative about a solution you all offer as we were looking to solve some problems in our OR. He was very forthright and advised that this product would not work for us given our needs and setup. Again, I appreciate honesty. I appreciate being forthright and really everything Denette said this product could do, it has done. In fact, it has exceeded our expectations.

Getting everything installed is one thing but getting your staff to embrace new technology is another. How have your team members navigated the change?

Simple technology is the key and it’s very clear that in just the few years that, Kit Check has been around, the product has evolved to the point where it can’t get much simpler than it is. The technology in and of itself is not rocket science. What’s kind of magical about it is, you put the whole tray or a bag in there and the thing somehow counts them up and knows exactly what’s in there. You press the button on the screen and in 5 seconds you have a read. It just cannot be simpler. The whole process is just so easy to use.

In fact, one of our pharmacists who isn’t the touchy-feely type, literally went over to the Kitcheck blue cabinet and hugged it in expression of how much she really likes the product! She is a very techno-savvy person but could not have been more impressed with how easy the product is to use and the accuracy of the resulting scan.

Now that things are running smoothly, what new technologies are you thinking about for the future?

I am really excited to see what other things we can do with Kit Check. It sounds like Kit Check is evolving and moving towards some neat projects. We are a small community hospital and we are not just about carrying out our profession and taking home a paycheck. We are here to make a difference in the lives of others and it seems like Kit Check is trying to do that too. I am impressed from top to bottom, I really love the product.

Interested in learning how Kit Check can help your pharmacy automate kit, tray and OR drug management? Drop us a note and we promise you’ll fall in love with us.